About Décor and Fabricage

Who we are

We welcome you to the "Décor and Fabricage"- a wonderful world of interior fits and stainless-steel craftsmanship. Located in the heart of India's vibrant capital, New Delhi, we showcase the craftsmanship of distinction with an array of interior design solutions, making artistry meet functionality.

Shrinking space is a significant challenge in metro cities, and that catalyses vertical growth in interior design. Whether commercial or residential, hospitality or F & B, Business office or Gym, we provide a wide range of steel fabrication services & installation in Delhi and other cities and transform spaces perfectly.

100% Off Stainless Steel

A perfect fusion of 100% Off Stainless Steel and beauty, our Super bright and glistening stainless steel products catch your imagination.

Multiple Design

A perfect fusion of multiple design elements and beauty, our Multiple design products indeed draw your attention.

3D Model of Your Space

A perfect fusion of a 3D Model of Your Space and beauty, our 3D Model Space idea is a treat to your eyes.

Color Palette

A perfect fusion of Color Palette and beauty, our super bright colour palette inspires your imagination and creativity.

Our Services

Our Infrastructure - Unleashing our Brand Power

Infrastructural support has a significant role in supporting one's business journey. We are a continuously evolving organization, and in the past five years, we have invested in our modern factory premises, machinery, and technology, as well as upskilling our employees to cater to market needs. Today, we are well-equipped to manufacture world-class interiors and provide steel fabrication services that match global quality standards.

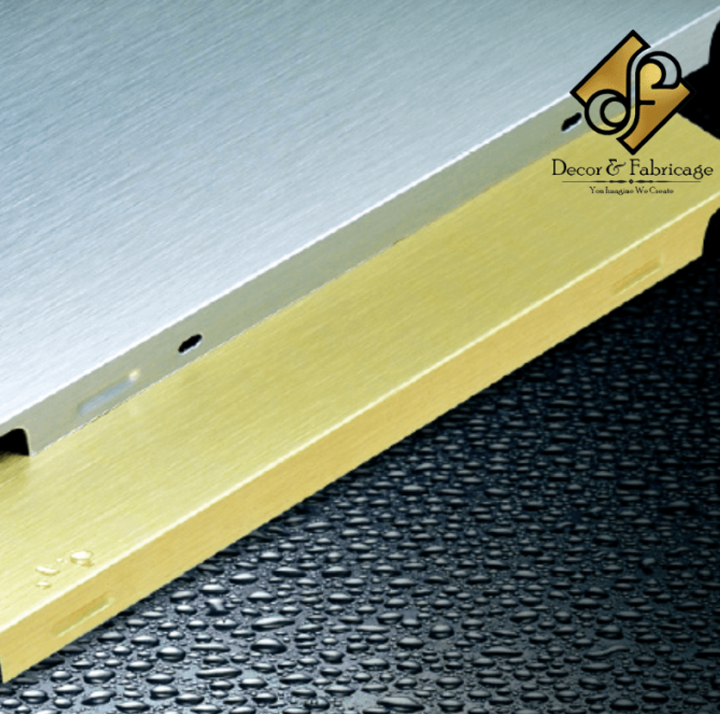

WAREHOUSING & PACKAGING

Our warehousing complex has adequate capacity to store our bulk Aluminum profiles & stainless-steel decorative profiles. We have experienced MIS and materials managers who entirely control the inventory and the quality of incoming and outgoing products. All the products are stored, segregated, and supported by a modern material handling system during dispatch.

Before the dispatch, every consignment is carefully packed to ensure safe delivery. The packaged goods are labelled with complete information and handling directions. We have defined SOPs for export consignments.

Stainless Steel PVD Coated Sheet in Delhi NCR

All About PVD Coating

PVD, or (Physical Vapor Deposition) is a coating process used in the industry.

One of the most regular PVD coating processes includes evaporation and sputtering (using magnetic enhanced sources or "magnetrons", cylindrical or hollow cathode sources).

All these processes occur in a vacuum at working pressure (typically 10-2 to 10-4 bar) and generally involve the bombardment of the substrate to be coated with energetic positively charged ions to promote high density.

Reactive gases like nitrogen, oxygen and acetylene are pumped into the vacuum chamber during metal deposition to create various compound coating compositions. The result is a powerful bond between the coating and the tooling substrate and the film's tailored physical, structural, and tribological properties.

Industry applications for PVD coatings are constantly growing. That said, PVD coatings can be separated into two comprehensive categories: functional and decorative.

Functional PVD coatings are engineered to improve a tool's or component's life and overall performance, thereby reducing the cost-per-part in manufacturing.

Practical PVD coating examples include Titanium Nitride (TiN) on an HSS end mill.

Decorative PVD coatings improve the appearance of a part and provide some wear resistance characteristics: improvements to both form and function. An example of decorative PVD coating would be the deposition of a Zr-based film onto a stainless-steel door handle to provide a brass-coloured coating, but with wear and tarnish resistance that is better than natural brass. We at Décor and Fabricage have mastered and applied the process to our quality PVC-coated sheets production process.

Metal Fabrication in Modern Interior Space

Metals have been integral to interior design, whether residential, commercial, F&B, hospitality, etc. Although there are several applications in the real estate sector, like building frames and Wall and ceiling cladding, the decorative side of metals is currently applied in interior designing in Delhi. Especially styling with perforated metals is common; you often come across it.

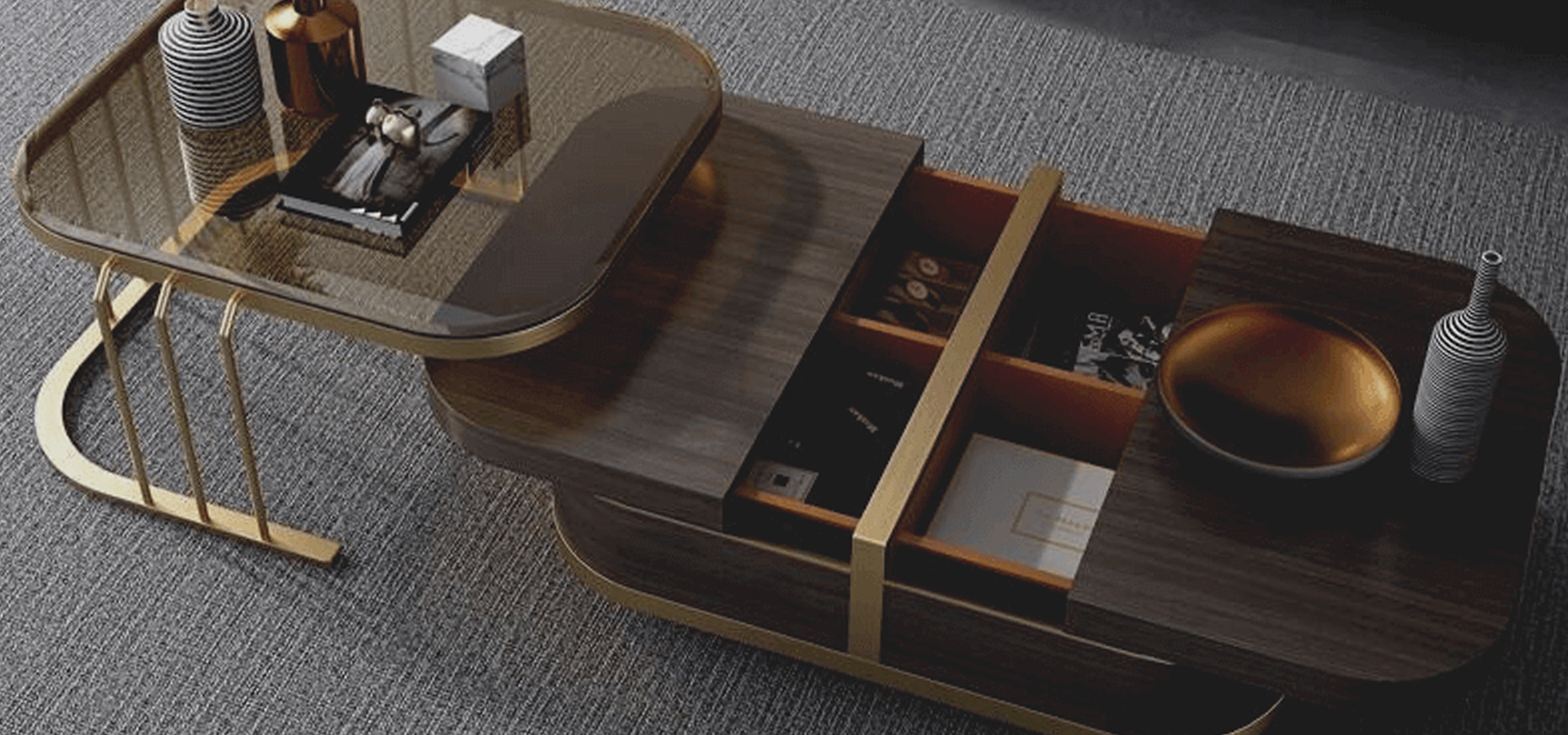

Décor and Fabricage specialize in incorporating metals like steel and aluminium in the interior space, making the design impact more visible. Metals contrasted with other materials, including glass and wood, add an elegant touch to your interiors, transforming the space into art. Our aluminium edge and handle profiles have a wide range of applications for furniture, landscape designs, real estate and modular kitchen space.

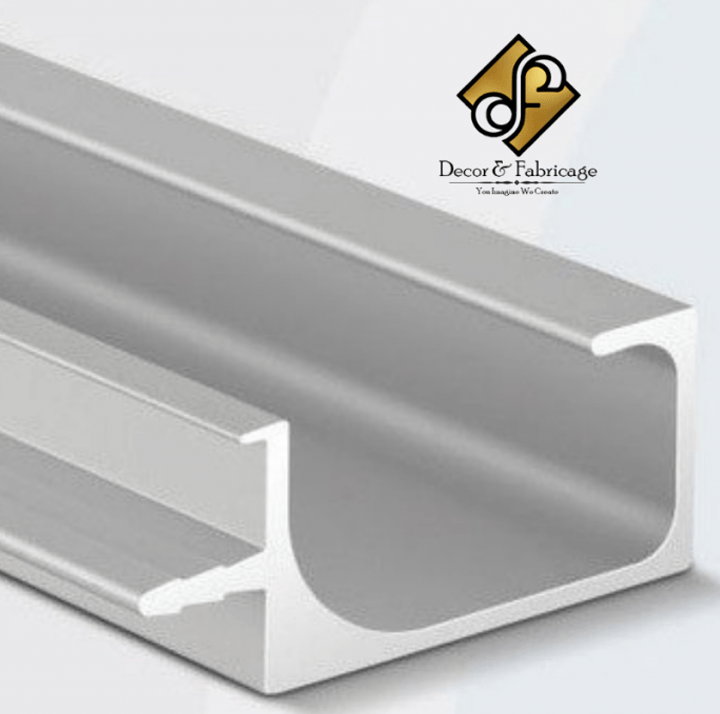

Décor and fabricated aluminium profiles are made of aluminium alloys and subsequently transformed into shaped objects through extrusion. Aluminum's unique combination of physical characteristics mostly depends on this process. Aluminium extrusions are used in several fields because this metal is Strong and stable.

Steel Fabrication Services & Installation in Delhi

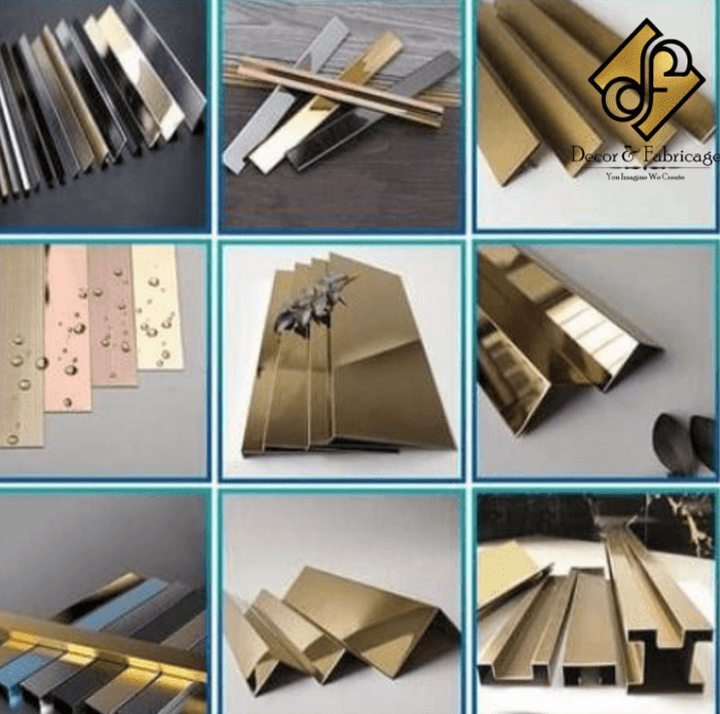

DÉCOR & FABRICAGE is a reputed manufacturer, importer & supplier of Stainless-Steel Profiles, Stainless steel fabrication services & installation in Delhi. We fabricate SS profiles, including T, U, L, Louvers profiles, customized profiles and plain Pattis using quality raw steel procured from certified vendors and advanced machinery under the supervision of our operation team.

We provide these metal profiles in various grades, sizes, thicknesses, and lengths and in customized configurations per various industries' demands at reasonable prices.

Steel Fabrication involves various techniques in stages applied and transforming primary metal into predefined shapes ready for installation. It includes manipulation techniques at different stages like shot blasting, cutting, blending, welding, and coating.